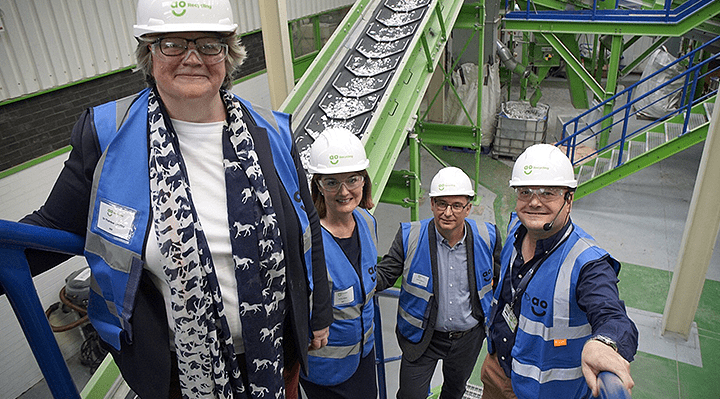

Government minister Dr Thérèse Coffey MP officially opened our very own recycling plant in May.

Our amazing facility will process more than 700,000 appliances in its first year of operation and will recycle a quarter of the fridges thrown away annually in the UK!

Dr Coffey toured the state of the art plant in Telford, which has created more than 200 jobs in the town. Here’s what she had to say:

“Congratulations to AO. This is a significant step by a British business to increase our capacity to recycle fridges and other electrical household appliances. Although collection and recycling of household electrical items is increasing, we all have a responsibility to our environment and it is only through businesses, consumers, and government working together that we will recycle more and protect our environment for the next generation.”

Most of the appliances arriving at the site for recycling, or for refurbishment and resale, will have arrived from our very own customers! The plant is equipped with cutting edge technology to handle all aspects of the complex fridge and LDA recycling process.

A repair and refurbishment operation ensures appliances which can be sold on as secondhand items are given a new lease of life. Cardboard packaging from our customers’ new products are also be recycled at the site.

For fridges which have reached the end of their working life, the first stage of the recycling process involves removing hazardous oils and refrigerants, as well as valuable compressors.

Then, appliances are deposited into an 80-tonne shredding machine built exclusively for AO Recycling by Austrian firm Andritz. Dubbed ‘Bertha The Big Green Recycling Machine’ the shredder uses large rotating steel chains to smash the fridges and LDAs into small pieces inside a sealed chamber.

The remaining plastics, metals and insulation foam are then separated and sorted at the plant for recycling. Dangerous gases including CFCs in older fridges and pentane in newer ones are also safely removed during the process.

Steve Caunce has said:

“With AO Recycling and this fantastic facility at Telford we’re completing that ‘closed loop’ system where we have a stake in a large part of the supply chain from purchase of a new machine to safe disposal at end of life.”

“AO Recycling Telford is trailblazing a new approach to electrical goods recycling in the UK which will have benefits for society, the environment and our economy. At the heart of that approach is the principle that the retailer should take away unwanted items from their customers. We’re leading the way with our first plant in Telford and believe this is the start of a revolutionary new way of doing things.”

We have set out our ambitious plans to transform WEEE recycling in the UK with our recently published Document for Change.

Published last year, the document is a response to the Government’s WEEE (Waste Electrical and Electronic Equipment) Regulation Consultation, and is a call to action to the Government, recycling industry, retailers and producers to work together to increase the amount of WEEE recycled in the UK. The policy document has set a bold target of increasing home collections of unwanted electrical appliances to 70 per cent.

Anthony Sant continued:

“We have heard a lot recently about the problems associated with plastic waste. However, waste electrical appliances should also be a priority as this is a hugely challenging waste stream. We believe we need to shift the emphasis to a system based on retailer take-back – and that consumers should rightly expect this as standard when they buy a new product. It will require a collective approach to managing WEEE from retailers, producers, recyclers and policy makers to increase home collections from customers.”